Innovation

The value of innovation

Our industrial capacity at the service of cutting-edge architecture

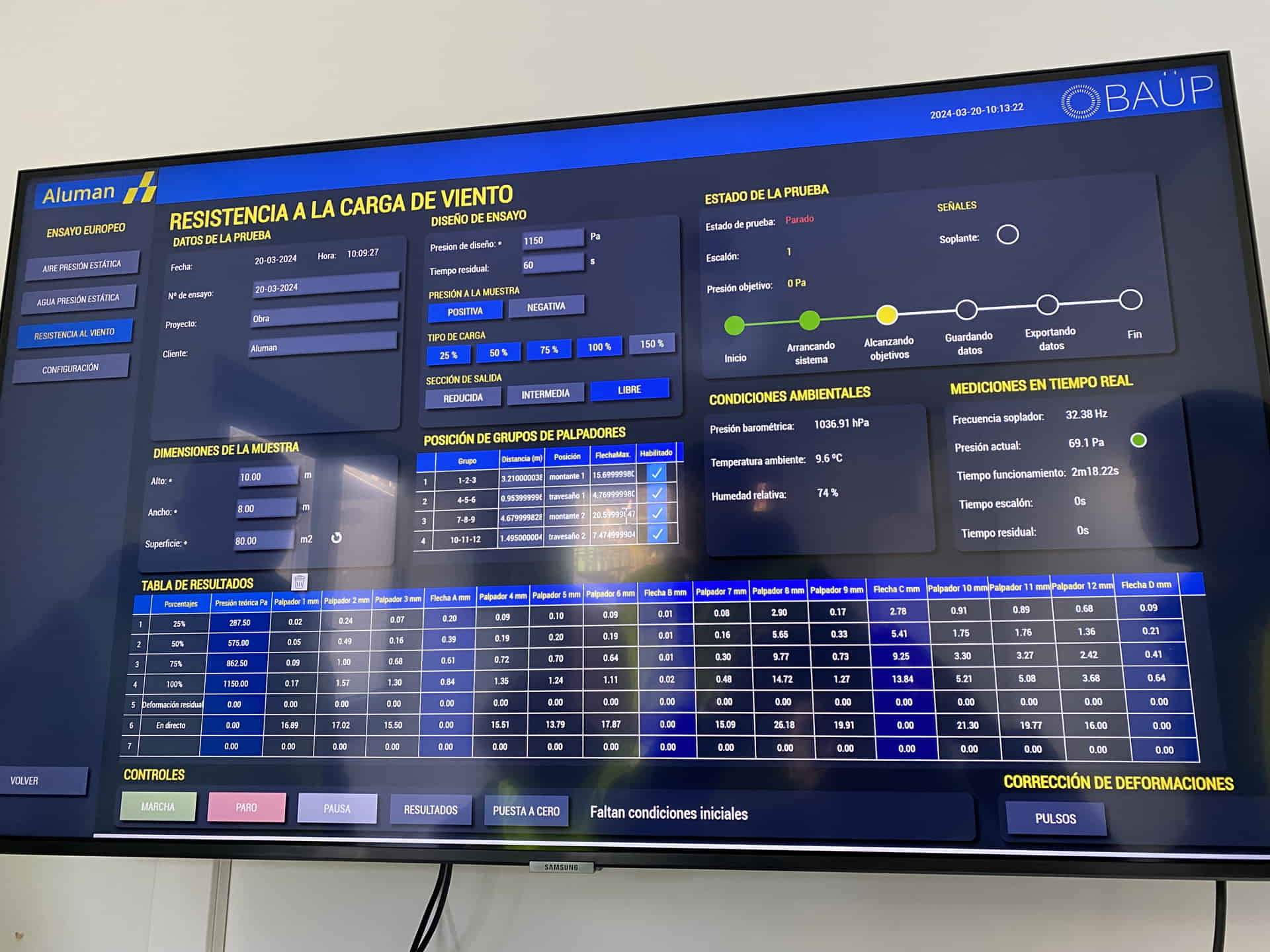

Aluman Lab

Aluman LAB is the flagship of Aluman. Our test bench, together with the management team, are vital to of the design phase, when the performance of the systems is checked and certified before manufacture and installation on site.

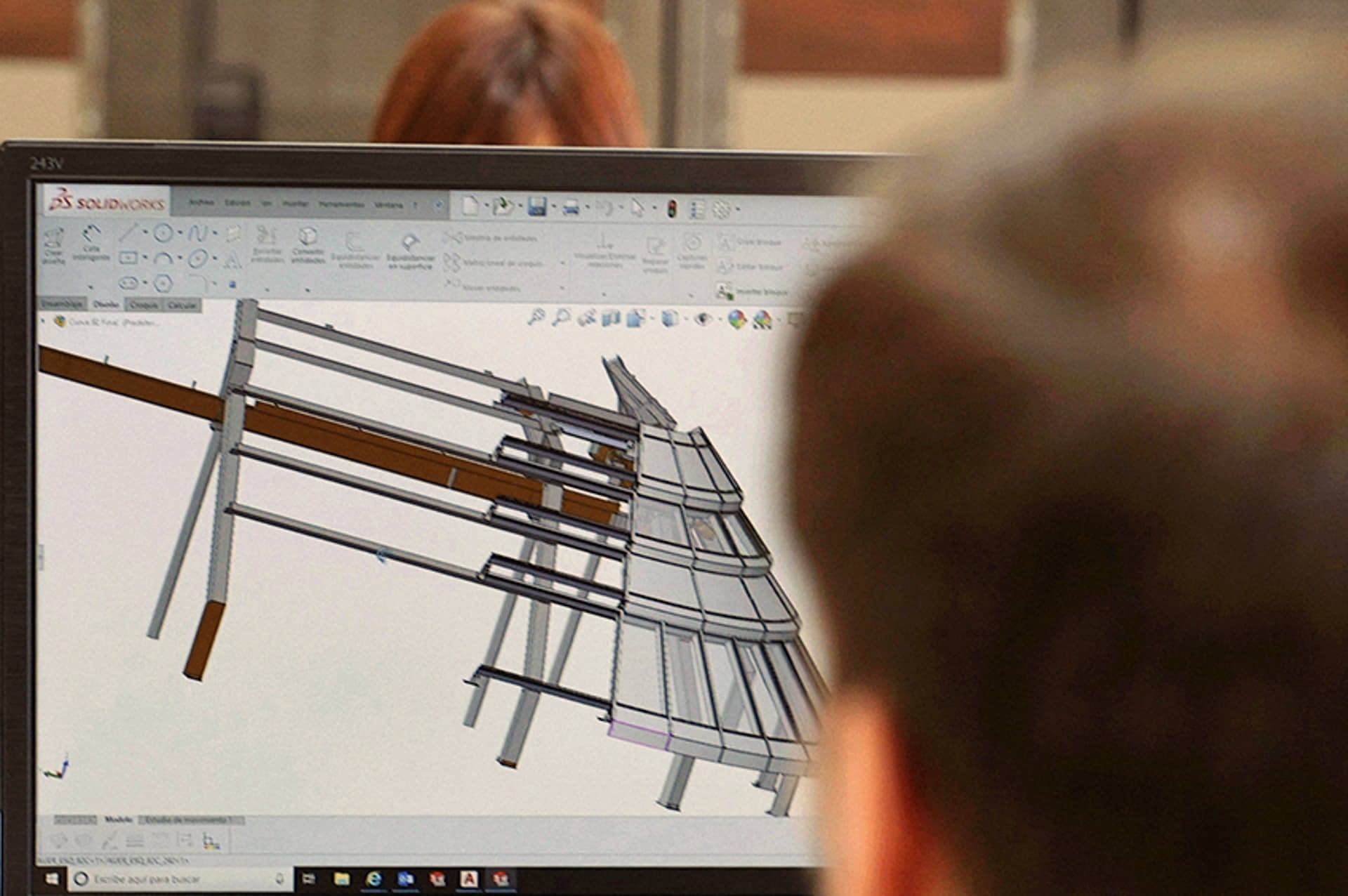

Value engineering

We have a highly specialised team of engineers in programming, automation, parametrisation and low code. These skills enable us to offer construction solutions adapted to the specific needs of each project and its level of specialisation.

Industrial capacity

An artisan spirit and a powerful industrial and innovative capacity come together to make any building project design possible.

Automation, robotisation and flexibility to configure our modular processes and lines and adapt them to the dimensions and needs of each project, with a constant focus on circularity and sustainability.

Automation

Technology and innovation to optimise every process, offering precision, efficiency and quality

Versatility

Flexibility and the capacity to adapt production to any project, with customised spaces and flows.

Expertise

A highly qualified team with in-depth knowledge of the sector that provides value to our projects

- 42,000 m2 of production space

- Machining centres

- Welding and metalwork

- Laser cutting and welding machinery

- Modular lines

- Injection machinery

- Cutting, folding and machining units for sheeting and panels

- Lacquering plant

- Manufacture of metal and wooden furnishings

- Aluman systems for stick and modular curtain walls

- Aluman PVC and aluminium carpentry

- Window and curtain wall services provided by aluminium profiling and installation companies

- Manufacture of luminaires and signs

- Material stock warehouses

- Laboratory and test bench

Operational excellence

At Aluman we provide high logistical capacity and rigorous planning to ensure that units arrive at the right time, optimising cubic capacity, shipping and storage at the workplace.

Our project managers and site managers monitor the project on site, from the early stages of assembly, coordinating and managing resources and schedules and ensuring excellent quality standards throughout the process.

A team of qualified technicians, with expertise and know-how to complete highly complex structural envelopes.

We meet project milestones while always maintaining the highest levels of safety and prevention.